We make an anchor with our own hands for a PVC boat. Anchor Denfort using a grinder and a drill

A little earlier, we already talked about how to make do-it-yourself anchor for boat PVC without the use of any tools other than a drill. Then it was about making a simple suction cup anchor from an old brake disc. This time let's talk about a more complex unit - the Denfort anchor.

How to make a Denfort anchor at home, with your own hands, has already been told many times, shown in the video and in the drawings. Why else talk about it? But why. In all articles and video reviews, welding is required to create it. Our task is to assemble the anchor without using a welding machine, using only a drill, a grinder (or a hacksaw), a pair of ordinary heads for tightening nuts and with our own hands.

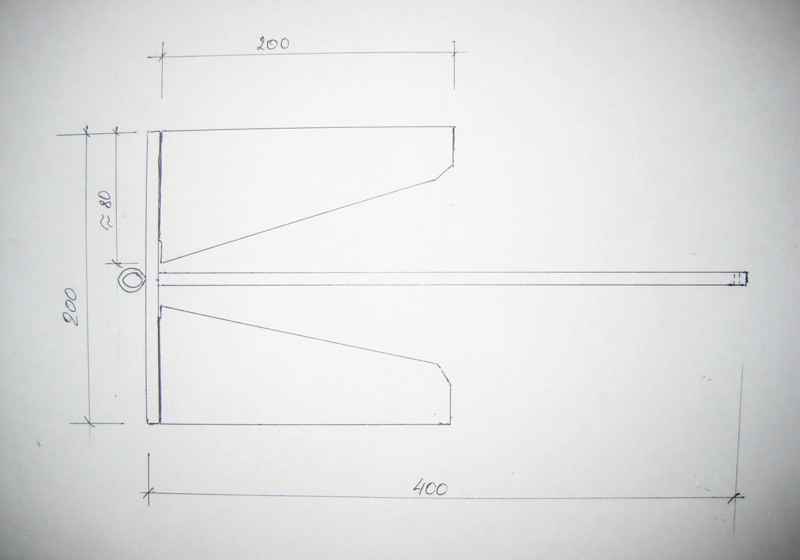

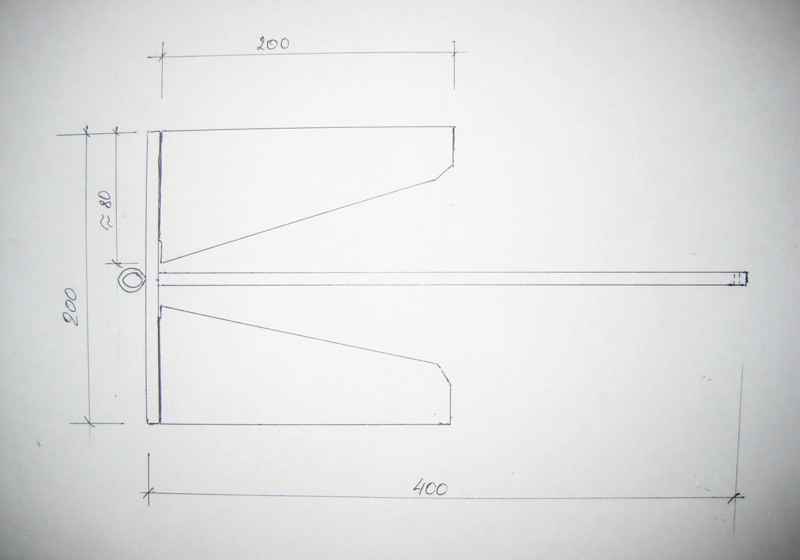

This time we will be guided by a simple anchor drawing. However, the drawing is loudly said, let's get by with a sketch drawn by hand, indicating the main dimensions, in this case this is more than enough.

REQUIRED MATERIALS AND TOOLS

Materials:

- aluminum pipe 30x2x600 mm (you can use steel, and the cross section can be changed, it’s just that we had this one at hand);

- steel sheet at least 200x200 mm (preferably 3-4 mm);

- bolt 8x60 = 1pc;

- nut M8 = 3 pcs (preferably self-locking);

- body washer D8 = 2 pcs;

- bolt 5x35 = 2 pcs;

- nut M5 = 2 pcs;

- eye nut and bolt corresponding to it = 1 pc (if you attach the rope differently, you can do without it);

- a small ring (preferably, but not necessary, paired with a lower mount is used to extract the anchor when hooked).

DIY anchor making tool:

- drill;

- grinder (you can get by with a hacksaw for metal, but it will take more effort and time);

- head 13 mm = 2pcs;

- extension L-125 = 2 pcs (you can use something else, for example, a large slotted screwdriver, you will understand further).

ANCHOR MANUFACTURING PROCESS

First, let's make paws for our anchor. To do this, I recommend drawing them first on a piece of cardboard, cut out a stencil, on it, a little later, we will cut out the steel ones. In the meantime, for "trying on", we'd better use cardboard. The shape of the paws - which one is more to your liking.

Next, we take our pipe and cut it into two parts - 200 and 400 mm. In the shorter one, we make two cuts in length and width in accordance with our cardboard paw layout. In the center, we cut out a segment 34 mm wide (i.e., slightly larger than the diameter of the pipe) and ½ diameter deep (it can be a little deeper). We drill 5 holes - 1 in the center for the eye bolt and 4 pieces with a diameter of 5 mm for attaching the anchor paws (in principle, 2 are enough, one on each side). You should get the following result.

Next, we take our pipe and cut it into two parts - 200 and 400 mm. In the shorter one, we make two cuts in length and width in accordance with our cardboard paw layout. In the center, we cut out a segment 34 mm wide (i.e., slightly larger than the diameter of the pipe) and ½ diameter deep (it can be a little deeper). We drill 5 holes - 1 in the center for the eye bolt and 4 pieces with a diameter of 5 mm for attaching the anchor paws (in principle, 2 are enough, one on each side). You should get the following result.

After that, we cut out the paws from the metal, insert them into the slots, drill holes in them in accordance with the holes in the tube.

After that, we cut out the paws from the metal, insert them into the slots, drill holes in them in accordance with the holes in the tube.

We take the second part of the pipe (400 mm). At one end we make oblique saw cuts so that it can rotate in the central cut of a short tube, but in such a way that there is enough space left for the hole for the M8 bolt, which will act as the axis of rotation. At the other end, just drill holes.

Now it's time to assemble the whole structure. We fasten the eye nut (an anchor rope will be tied to it).

Now it's time to assemble the whole structure. We fasten the eye nut (an anchor rope will be tied to it).

We make the axis of rotation - we twist the bolt, nut and washer in this way.

We make the axis of rotation - we twist the bolt, nut and washer in this way.

We insert the pipe into the pipe, install the axis and fix it - we wind the nut, almost to the end, but do not tighten it, put the washer on and now we tighten everything with another nut. Here you will need heads and extension cords (if there are no extension cords, you can use a slotted screwdriver of the appropriate width). The end result should be something like this.

We insert the pipe into the pipe, install the axis and fix it - we wind the nut, almost to the end, but do not tighten it, put the washer on and now we tighten everything with another nut. Here you will need heads and extension cords (if there are no extension cords, you can use a slotted screwdriver of the appropriate width). The end result should be something like this.

Now it remains to fasten the paws of the anchor, and hammer the ends of the tube with wooden plugs, they will eliminate the backlash of the paws and that's it.

Now it remains to fasten the paws of the anchor, and hammer the ends of the tube with wooden plugs, they will eliminate the backlash of the paws and that's it.

With this method of binding, it is advisable to install a weak ring at the end of the handle (you can use a bunch of keys) and tie a rope. However, there are different ways of fastening that ensure the removal of the anchor when hooked, choose the one that you like best.

With this method of binding, it is advisable to install a weak ring at the end of the handle (you can use a bunch of keys) and tie a rope. However, there are different ways of fastening that ensure the removal of the anchor when hooked, choose the one that you like best.

Of course, it turned out to be a little unpresentable and not too neat, but we didn’t think about beauty. The task was to try to make a PVC anchor for the boat with our own hands, specifically a folding Denfort anchor, without using a welding machine, only with the help of a tool available to everyone. It seems to have worked out.

updated: September 26, 2018 by: Sergei